Glove Manufacturer Tips: 4 Ways To Deal With High Leather Costs

Posted by ROGER HEUMANN

n my last trip to China, I had dinner with a leather supplier who represents many tanneries.

Our discussion turned to leather prices, which continue to rise.

While ultra premium brands can absorb higher material prices, that’s not the case for most brands we work with.

Here are some thoughts about how to maintain glove quality and margins, as we plan for another year of continued high leather prices in 2015.more

2015 Outlook: High Leather Costs, and other Challenges

There’s an expression: “Costs rise like a rocket, and drop like a feather”. You would think that lower oil prices would ripple throughout the supply chain and have a positive impact on costs – but we aren’t seeing that yet.

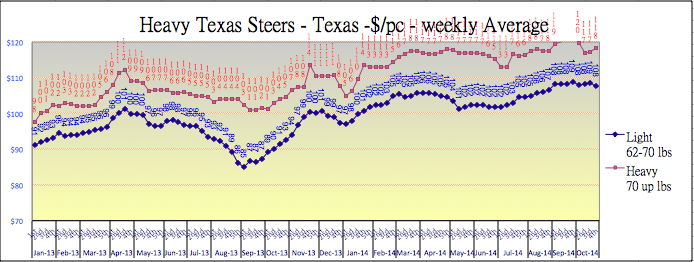

As the chart below shows, rawhide costs have risen steadily, and our projections are for costs to stay high.

In speaking with my tannery sources, it’s hard to understand why the cost of the rawhides is not dropping down even slightly. Some suggest it’s due to strong demand by the shoe industry for winter footwear.

Whatever the case, rawhide costs are not dropping, so we must become creative as we source and design product.

4 Ways to Manage Rising Glove Leather Costs

Even as leather is the first or second most significant item on a glove cost sheet, there are still ways to protect profit margins.

Here are 4 ways to offset higher leather costs:

- Look for alternative sources and suppliers — for instance, less expensive sources of hides from countries like Pakistan, or less expensive substitutes for cowhide like goatskin, can help keep costs down.

- Make greater use of leathers with more forgiving finishes, such as grained leathers, embossed leathers, casual shrunken leathers, etc. which allow for a lower grade of hides to help offset the high cost.

- There have been major strides in the hand feel that has been achieved with man-made alternatives to leather. In some cases, PU looks and feels so much like leather, one wouldn’t bother to read the label.

- Offset leather cost with savings on other items. During the glove development process, an experienced glove designer will look for alternative trims, hardware, linings and other components to preserve the overall glove design within the cost allowance.

Cutting yields may present another opportunity. And lower oil prices should eventually start to create favorable variances for transportation.

One Caution to Keep in Mind

When it comes to effective purchasing, the first instinct is always to cut costs. But every move has consequences to keep in mind:

As you evaluate alternatives, you may be interested in reading more about the hidden costs of glove manufacturing:

Final Thoughts: 2015 Glove Manufacturer Challenges

In the face of high leather prices and other cost challenges, we continue to explore creative new sourcing solutions, so when our customers ask “What’s New?” we can delight both the product executives, and their accountants.

When developing new product and sourcing solutions, as long as we keep the end customer’s needs in mind, we will all do well.

What’s in your crystal ball for 2015?

TAGS: